Product group HSM Crusher 1049 SA

Product group HSM Crusher 1049 SA

HSM PET-Crusher 1049 SA As a result of the HSM solution, the space required for returned... more

HSM PET-Crusher 1049 SA

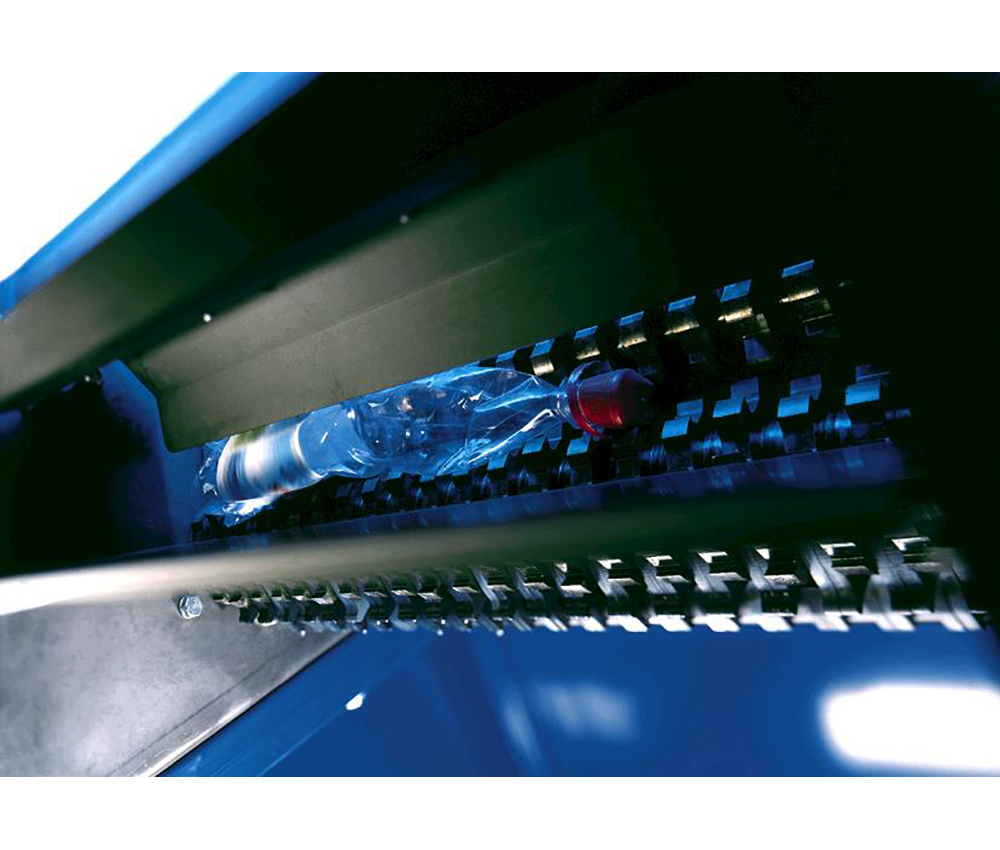

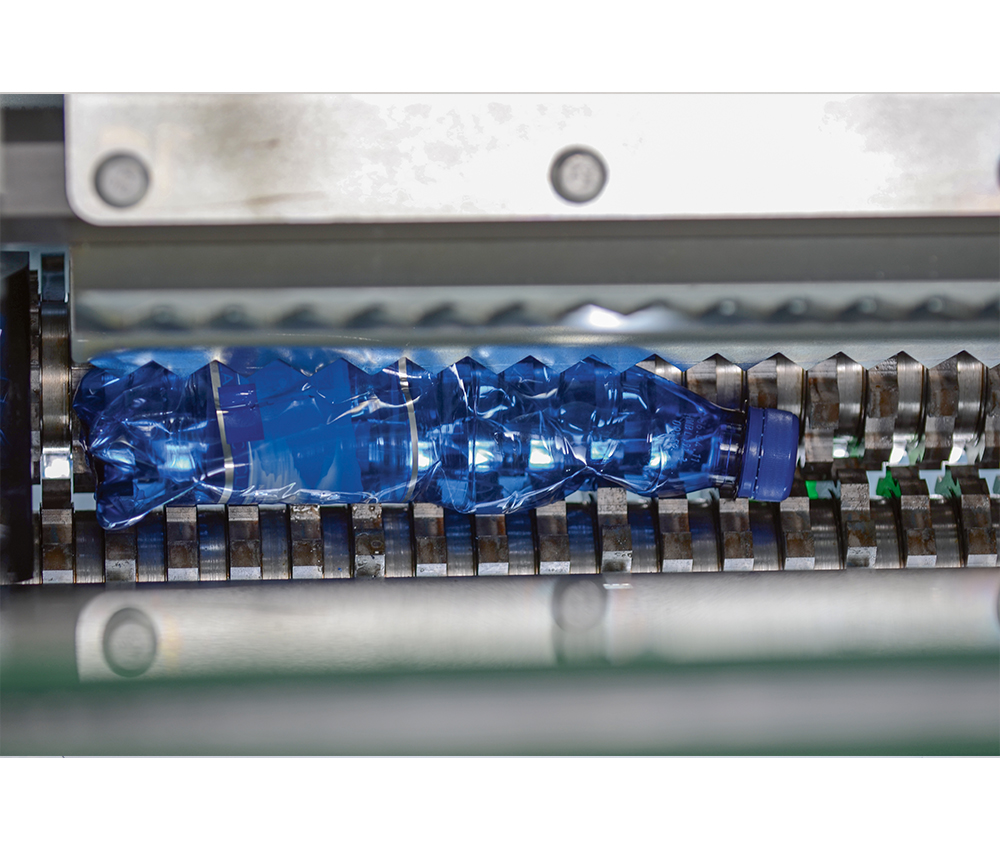

As a result of the HSM solution, the space required for returned empties is reduced to approx. 25-30 % of the original volume and as such, also reduces the time required for disposal. The special roller system perforates and crushes the containers. The sidewalls mesh into each other, making the reduction in volume permanent. Crushing has an additional advantage: deposit plastic bottles and cans are reliably invalidated.

An efficient system for the volume reduction of PET bottles and cans down to 1/3 or 1/4 of the original

Throughput per hour up to 2400 PET bottles (1 litre)

The cutting head can also be used in combination with a deposit return machine

Crusher rollers made of specially hardened and ground steel, completely resistant to wear and very strong, for a long service life

Automatic switch off after two minutes to save energy - available for continuous operation

Manual control of the machine via easy-to-use keypad with forward, reverse and stop functions

LED display provides information on the current status of the machine (ready, overload, door open, container full)

A dosing shaft with integrated blades ensures that the plastic bottles and cans are fed reliably

A scraper system removes the compressed plastic bottles and cans from the crusher rollers to prevent blockages and downtime while clearing