HSM VK 7215 75 kW FU

HSM VK 7215 75 kW FU

Channel baling press HSM VK 7215 For professional disposal management or larger industrial... more

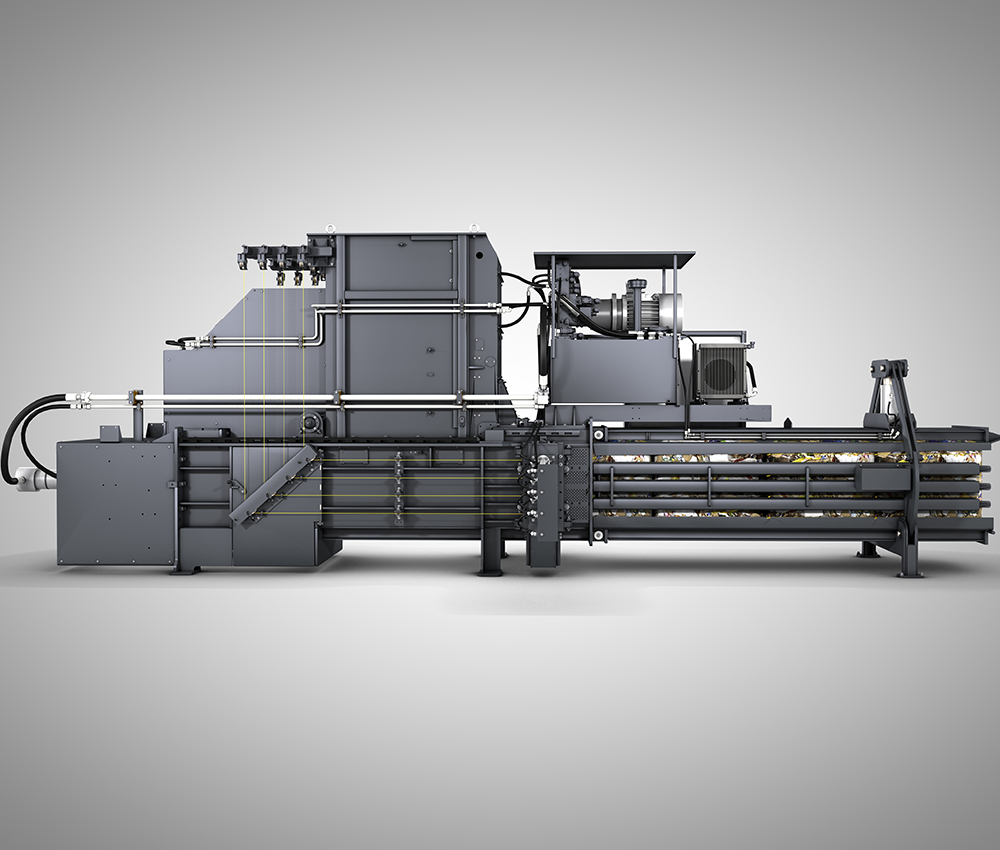

Channel baling press HSM VK 7215

For professional disposal management or larger industrial applications with high throughput rates - Throughput up to approx. 498 m³/h

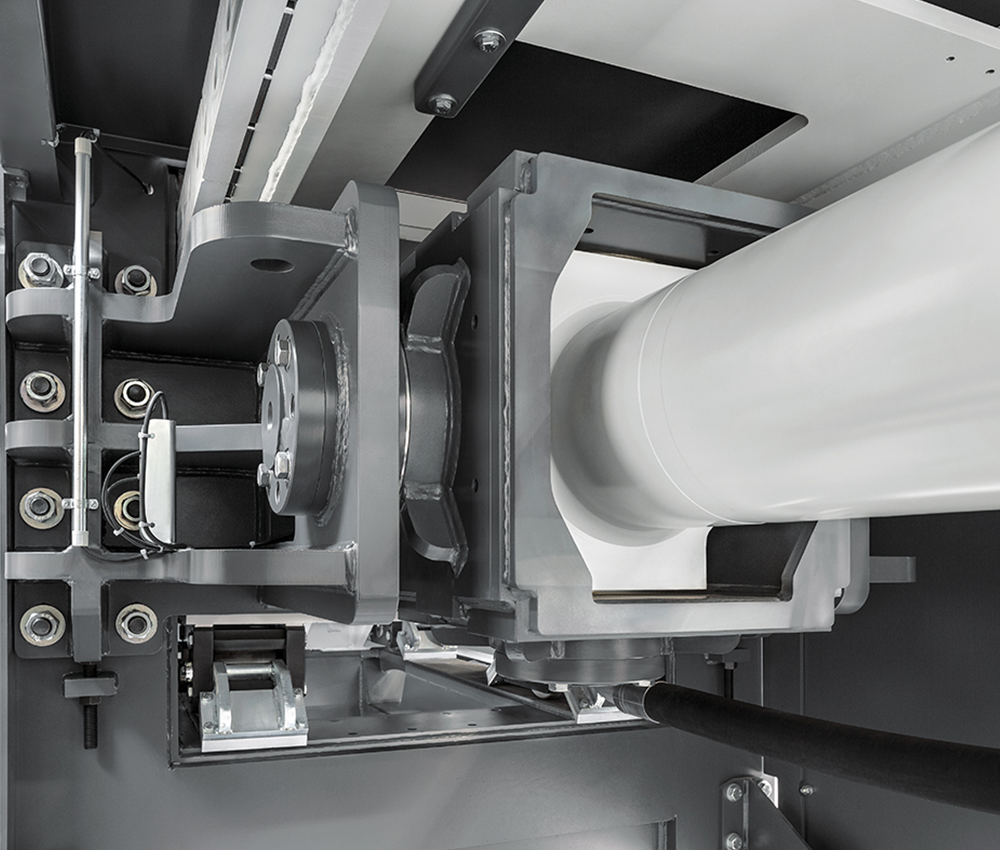

Gimballed press cylinder system - Reduced wear on the pressing cylinder and press ram guides

Determining the bale length exactly, even in the case of frequently exchanged material

Available as an option suitable for residual waste (with wear-resistant steel)

Versatile solution for materials up to approx. 60 kg /m³ bulk weight

Available as an option with frequency-regulated drive – saves 40 % of the energy used by standard drives

Control of the pressing process via light barrier. Suitable for continuous loading with conveyor belt, air feeding or similar

Optimised bale dimensions and bale weights for efficient truck loading

Suitable for cardboard, plastic film and compressing DSD goods, UBC as well as PET bottles (other materials on request)

Fully automatic 5-fold strapping for optimal bale result also with expansive materials

Technical data "HSM VK 7215"

| Order number: | 6445005 |

| Pressing power: | 720 kN |

| Specific pressing power: | 87,3 N/cm² |

| Driving power: | 75 kW frequency-controlled |

| Voltage / Frequency: | 400 V / 50 Hz |

| Cycle time when idling vacío: | 8,9 s |

| Volume throughput in idle operation (theor.): | 498 m³/h |

| Volume throughput at 50kg/m³ (theor.): | 24.9 t/h |

| Loading aperture width x Loading aperture length: | 970 x 1500 mm |

| Bale width x Bale height x Bale length: | 1100 x 750 x 600-2000 mm |

| Length x Width x Height: | 10750 x 4159 x 3260 mm |

| Weight: | 24 t |

| Type of consumables: | Wire |

| Press material: | Plastic film, Mixed paper, Cardboard, Punch waste/residue, Big Bags, HDPE / LDPE hollow containers & plastic bottles |

Smurfit Kappa GmbH

Confidence in operational reliability

Read more in our Case Study.

You want to see how a VK 7215 works? See here a HSM VK 7215 at work at Smurfit Kappa.

Offsetdruckerei Schwarzach Feinkartonagen Etiketten

It pays to have less volume

Read more in our Case Study.